Case Study: Replacement Of MUA Unit At Mount Saint Joseph Academy

Client: Mount Saint Joseph Academy, Flourtown, PA

Job: Replacement of existing MUA unit in Cafeteria/Kitchen

Mount Saint Joseph Academy in Flourtown, PA hired Chadwick Service Company to replace the Make-Up Air (MUA) unit in their kitchen. The MUA unit is an essential component of any commercial kitchen, pulling in outside air, conditioning it, and replacing what has been exhausted. Without a fine-tuned MUA unit, building pressure becomes negative, air quality issues arise, temperature control is a challenge and the environment becomes uncomfortable.

First, we replaced the VRF system

Before replacing the commercial HVAC’s MUA unit, we started the project with the installation of a Variable Refrigerant Flow (VRF) system. The VRF system is a modern HVAC technology that uses refrigerant as the cooling and heating medium. Since the VRF system is best suited for areas that need both cooling and heating at any given time, it was a good fit for an institutional cafeteria/kitchen.

As with mini split units, the refrigerant in a VRF system is conditioned by a single outdoor, condensing, commercial HVAC unit and circulated within the building to multiple indoor units. While the rest of Mount Saint Joseph Academy runs off split systems, rooftop units, boilers, and fan coil units, we determined that the VRF system would be the best option since it eliminated the need for additional ductwork. By using the VRF system, we only had to run electric, control wiring, and refrigerant and drain lines.

As there are no ducts in a VRF system, no temperature loss occurs as it does with traditional systems when treated air moves through the ductwork. The result is consistent heating and cooling at very high energy efficiencies. In addition to saving the client time and money, this commercial HVAC system also solved a pretty significant issue, which was a shortage of space above the ceiling.

Then we replaced the Make-Up Air unit

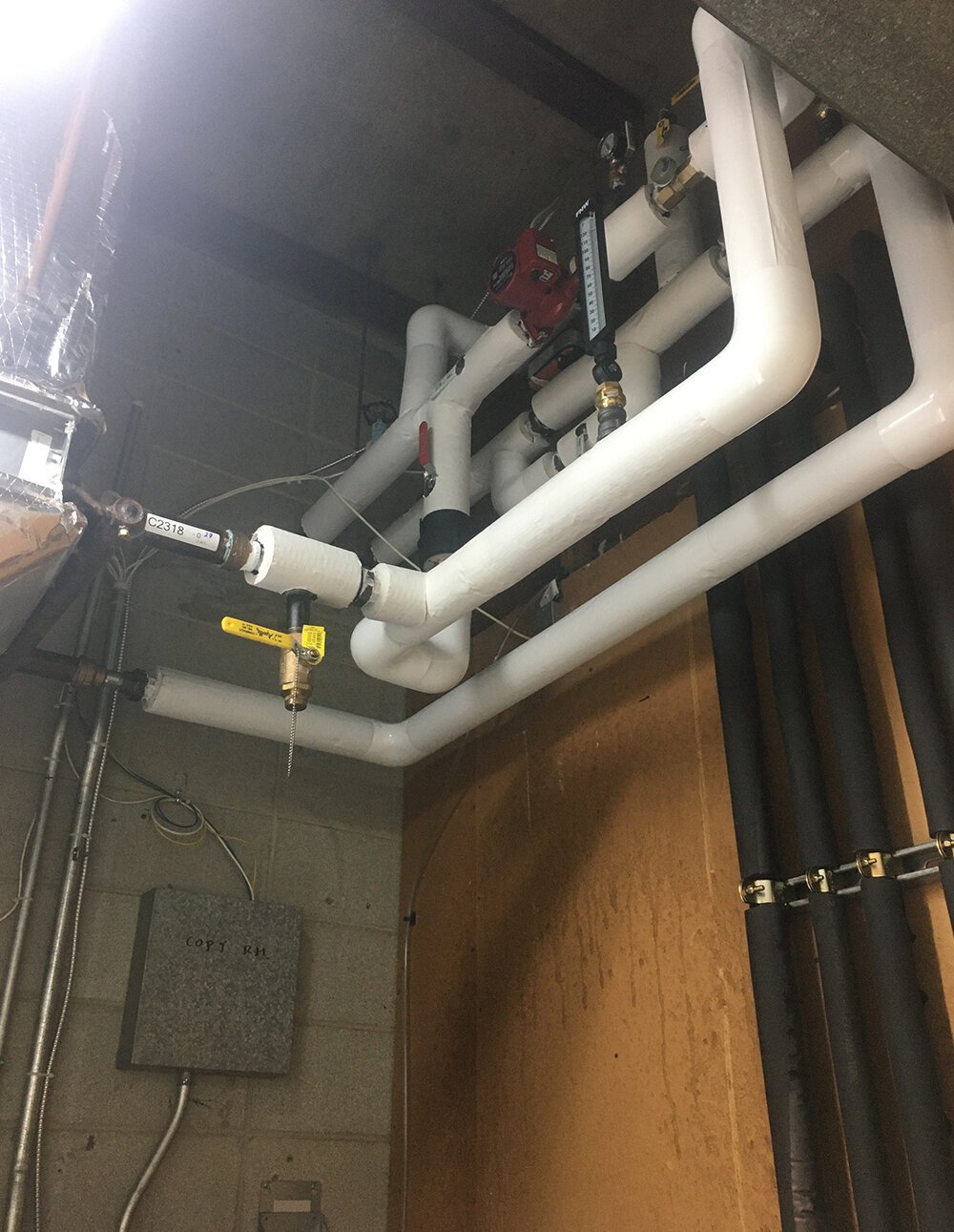

After installing the VRF system, we moved forward with the replacement of the MUA unit. We swapped the existing unit with one of the same size but included the addition of both a cooling coil (evaporator coil) and a reheat coil. The cooling coil’s function is to absorb the heat from the air in the building, and a new reheat coil heats the air in the supply duct, controlling the temperature to specific zones. A reheat system works by cooling air to a temperature low enough to condense or remove moisture for humidity control, and to offset the largest heat gain generated in the building. With the addition of the cooling and reheat coils, the newly designed commercial HVAC unit allows for tempered, outside air to occupy the indoor space, which not only accommodates the new VRF system’s fresh air requirements but brings everything up to code. All in all, this system provides the flexibility of delivering different amounts of cooling to various zones at distinct times.

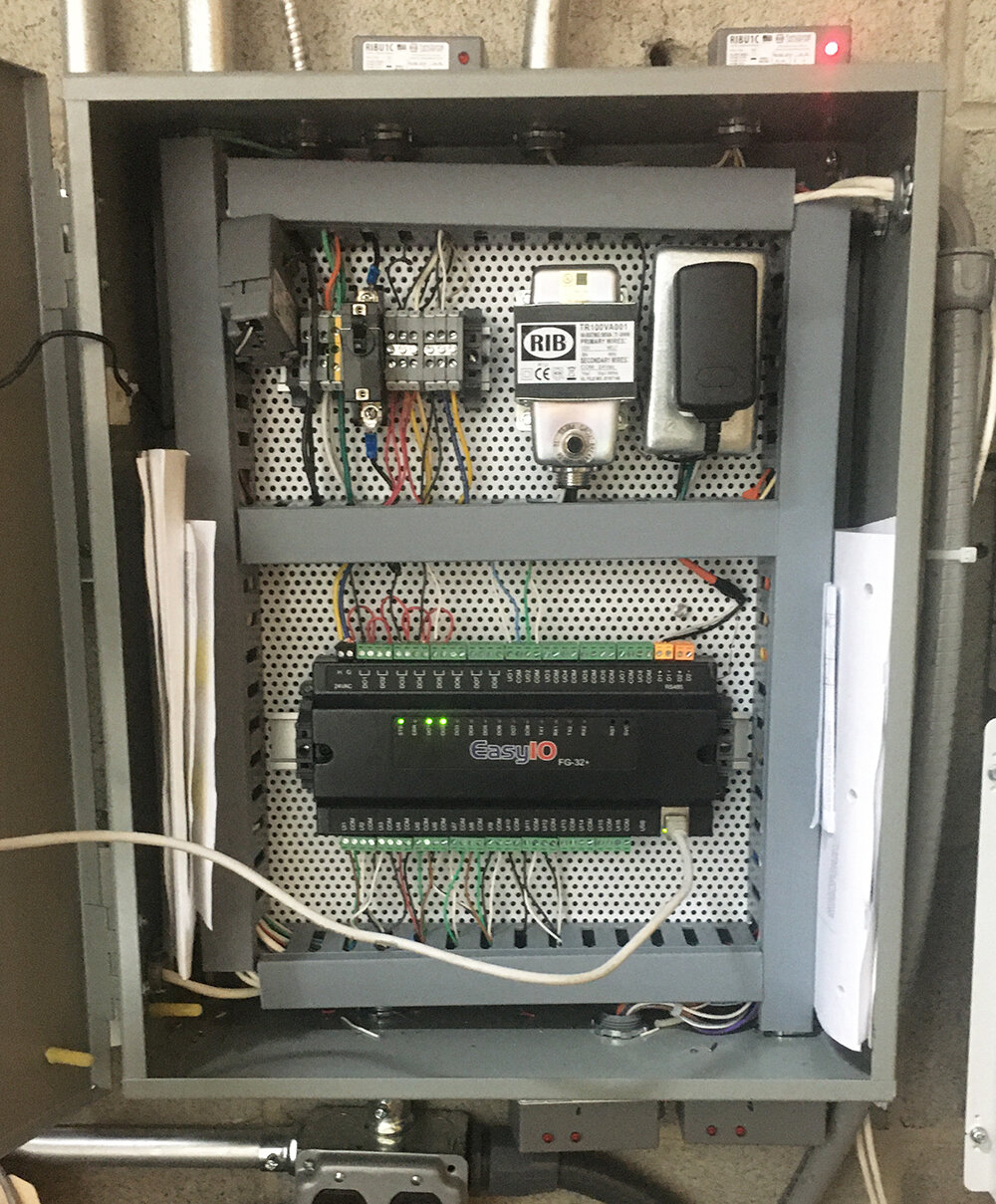

Altogether, installing the VRF system and replacing the Make-Up Air unit took only ten days to complete. This included the demolition and installation of the existing and new MUA units and the running and implementation of new controls. Only one challenge arose during the planning phase, which was the large amount of time spent with the engineer on the control side of things. In the end, we made sure we were extra diligent in the design of the new system, making sure that the occupants would be pleased with how the system operates.

Newer commercial HVAC systems, such as the VRF and MUA units mentioned, are energy efficient, require less maintenance and provide more bang for your buck. If you would like to request a consultation or discuss changes to your commercial heating and cooling system, please contact us.